Inland container terminal productivity strategies

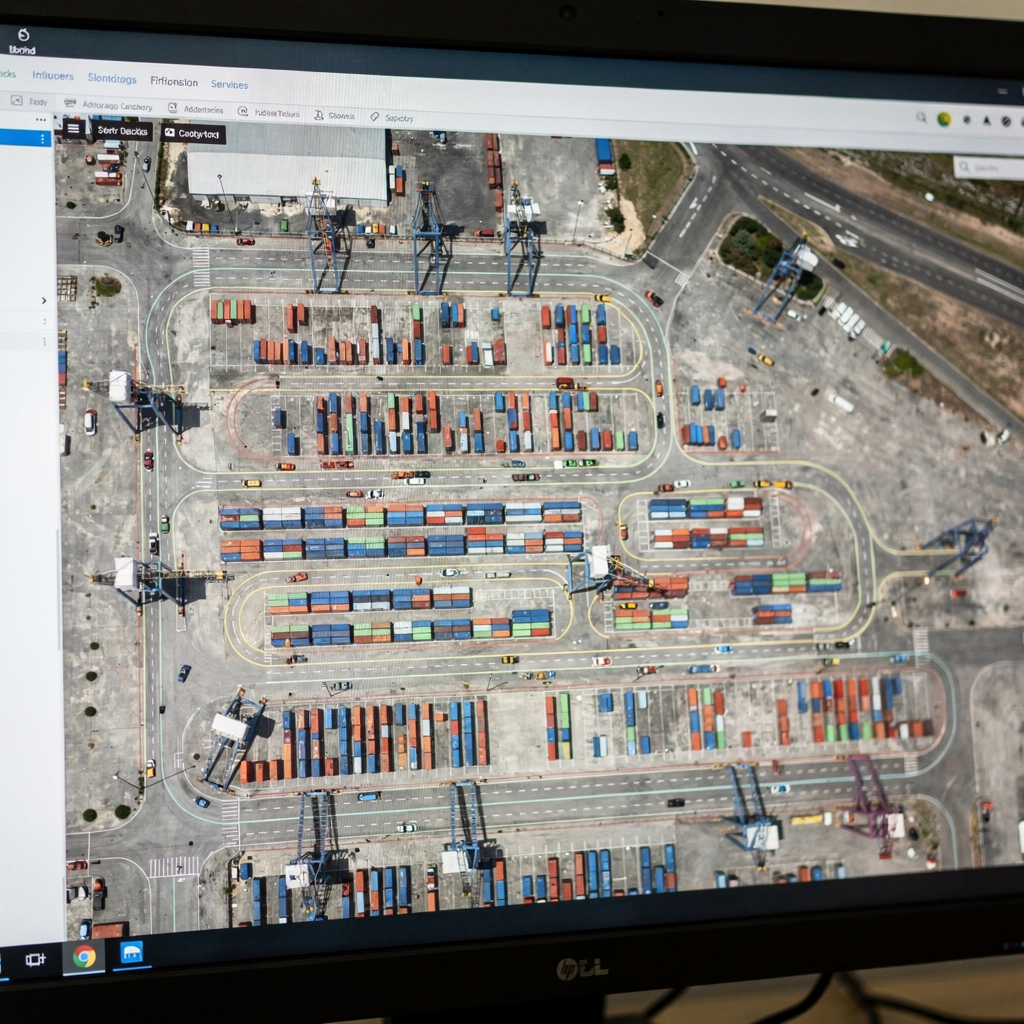

optimize terminal operations: Boost container terminal productivity

First, define the core indicators that drive terminal decision-making. Moves per hour, dwell time, and throughput act as primary performance indicators for any inland container facility. Next, relate those metrics to cost and service. For example, a steady increase in moves per hour improves vessel turnaround and yard flow. Also, dwell time reduction frees yard slots and shortens truck queues. Therefore, planners can reduce truck wait and total turnaround time by focusing on these metrics.

Second, benchmark current performance. Typical inland container terminals record 100–200 moves per hour on a busy quay or interchange block. For reference, studies show automation and data techniques often yield double-digit productivity gains, which translate into higher moves per hour and lower dwell. In addition, compare terminal performance to regional peers. That comparison reveals areas for quick wins and structural changes.

Third, employ process mapping and time studies to identify inefficiencies. Start with gate-to-yard flows and then examine quay handling and intra-yard moves. Use simple time-motion studies to quantify the container handling process and reveal idle times. Then, capture the data in a digital dashboard so the terminal operator and planners can act in real time. For deeper analysis, run what-if tests in a digital twin to validate fixes before deployment.

Fourth, align KPIs with operational targets. For example, set crane productivity targets per shift. Then, monitor equipment allocation and workforce sequencing to maintain steady throughput. Also, use appointment systems and slot planning to smooth peaks, which helps reduce congestion at the gate. In practice, terminals that combine clear KPIs with short feedback loops see measurable improvements in terminal performance and reduced reliance on individual operator experience.

Finally, embed continuous improvement routines. Use short daily reviews to catch drift. In addition, link findings to longer cycles for layout or investment changes. For terminals that want actionable methodologies, see our guide on container stacking optimization techniques for practical ways to reshape yard policies and free capacity. Together, these steps help boost productivity across container terminals while keeping the focus on tangible metrics.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

container terminal operations: Tackling bottleneck challenges

First, recognise the most common chokepoints. Gate congestion, yard stacking conflicts, and rail yard limitations often restrict daily output at a container port. For example, poor hinterland links can cause a 2–6% loss in productivity due to longer truck cycles and idle equipment. Therefore, quantify each source of delay before you invest. That clarity helps target fixes with the highest return.

Second, measure the effect of each constraint. Use short studies to identify how many moves occur per gate visit and how often straddle carriers or RTGs create traffic loops. Then, model the impact on throughput and vessel turnaround. Also, include quay cranes and their idle slots in the analysis. In addition, compare yard density against quay productivity to identify hidden trade-offs between stacking depth and crane productivity.

Third, apply infrastructure solutions where appropriate. Dedicated truck lanes, extended gate hours, and separate in/out lanes reduce queuing. Likewise, improved rail connections and scheduled block trains smooth hinterland flows and reduce peak surges at the gate. For instance, green field expansions and improved links have been shown to reduce dwell time and increase overall throughput in several seaport container studies (Good Practices).

Fourth, change processes to avoid stacking conflicts. For example, apply proximity stacking or dedicated lanes for empty and full containers. Next, use appointment systems to align truck arrival with yard availability. Also, consider extending gate hours to flatten peaks. Finally, provide real-time information to truckers and shippers so they drive only when slots exist; that reduces idle queues and improves port efficiency.

Fifth, deploy targeted technologies. Real-time truck queuing apps, automated gate readers, and remote checks reduce human handling at the gate. In addition, cross-equipment job prioritization reduces contention between quay cranes and yard equipment; our work on cross-equipment prioritization explains practical approaches. Consequently, these combined measures free space, cut delays, and help terminal operators sustain higher throughput.

automation and real-time systems: Streamline port terminal activities

First, automation delivers predictable gains. Automated Guided Vehicles, remote cranes, and smart gantries reduce variability in move times. For instance, terminals that combine automation with big data analytics report double-digit gains and faster moves per hour in industry studies. Therefore, plan automation in stages to manage risk and integration costs.

Second, focus on real-time coordination. Use real-time tracking and AI-driven scheduling to balance workloads among quay cranes, yard cranes, and AGVs. Then, allow systems to reassign tasks dynamically when delays occur. Also, ensure your automation stack integrates with the terminal operating system so that job assignments flow from plan to execution. For background on decoupling fleet logic from TOS, read our note on fleet control architectures.

Third, employ smart scheduling to reduce empty moves and rehandles. For example, reinforcement learning agents can suggest stows that minimise shifters while preserving crane productivity. As one expert noted, “Automation reduces dwell and increases steady moves per hour,” which directly improves throughput and reduces yard congestion (Loadmaster.ai). In addition, AGVs paired with ASC systems reduce truck interaction and smooth quay cycles.

Fourth, measure the gains from real-time systems. Case studies show up to 15% improvements in moves per hour and roughly 20% fewer delays when terminals combine automation with real-time orchestration and predictive KPIs (Operational performance research). Also, unified dashboards and alerting keep operators focused on exceptions instead of routine tasks. As a result, staff can move from firefighting to proactive optimisation.

Fifth, balance human and automated roles. Train operators to supervise and override safely. Also, phase in automate technologies while preserving operational governance and audit trails. For terminals planning such projects, our guide to AGV opportunity charging and fleet coordination provides practical deployment advice. Ultimately, the best outcomes come when automation complements human expertise and clear KPIs.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

simulation for stacking strategies: Enhance yard utilisation in container terminals

First, use discrete-event simulation to test stacking policies. Simulation lets you experiment with stacking strategies without disrupting live operations. For example, single-cycle, double-cycle, and proximity stacking each trade off driving distance, reshuffles, and accessibility. Therefore, simulate each option under realistic arrival patterns and vessel mixes to identify the best fit for your layout.

Second, quantify reshuffle reductions and travel distances. Studies indicate that optimized stacking strategies can yield a 10–12% uplift in productivity and reduce unnecessary reshuffles (industry analysis). Also, a simulation can reveal how yard density affects gross crane rate and yard crane interference. In addition, you can test how straddle carriers or RTGs perform under different density profiles.

Third, integrate simulation with scheduling and slot planning. By linking a digital twin to appointment systems and slot allocation, planners can predict yard stress points days ahead. Next, use simulation outputs to guide placement rules and container stacking rules so that cranes face fewer conflicts during peak shifts. Also, feed the results into a terminal operating system to automate placement decisions when conditions change.

Fourth, leverage reinforcement learning inside the simulator. RL agents can train on millions of scenarios to find stacking heuristics that beat historical practice. For more on simulated training and cold-start AI, see our explanation of how RL agents learn in a digital twin. Then, after training, validate the policies offline before controlled rollout.

Fifth, monitor post-deployment results. Use the same simulation models to replay live data and catch regressions early. Also, maintain a continuous improvement loop where simulation suggests small policy tweaks and the operator validates them in the field. In short, simulation gives you a low-risk platform to test stacking strategies that raise container terminal efficiency, lower rehandles, and protect quay productivity.

terminal management and terminal operating system: Driving logistics efficiency to improve container terminal productivity

First, a modern terminal operating system (TOS) centralises slot planning, appointment systems, and KPI dashboards. In practice, a TOS reduces manual handoffs and gives the terminal operator a single source of truth. Also, a unified TOS helps allocate quay cranes, yard cranes, and truck slots in a coordinated way. For further reading on integration risks and approaches, see our guidance on TOS integration risk mitigation.

Second, use the TOS to improve workforce scheduling and equipment allocation. Plan shifts so that crane crews and RTG teams match vessel windows. Then, use dynamic allocation to rebalance during delays. Also, embed KPI-driven guardrails so that planners act within agreed thresholds. That approach reduces reliance on a single senior planner and preserves tribal knowledge while fostering consistent results across shifts.

Third, implement slot-level controls and appointment enforcement. When truck appointments match yard availability, gate queues shrink and container movements become predictable. Moreover, TOS dashboards provide early alerts about upcoming peaks, which lets the terminal operator redeploy resources before service falls. For tracking predictive indicators and dwell forecasts, consult our piece on dwell time prediction.

Fourth, measure results from unified management platforms. Terminals that centralise control often report 10–20% reduction in dwell time and more stable throughput. In addition, automation of repetitive tasks frees staff to focus on exceptions, which in turn increases equipment productivity. Also, the TOS can surface performance indicators that expose hidden capacity and support smarter allocation.

Fifth, combine TOS with optimization layers. For example, add AI modules that recommend stow plans, stacking placements, and job priorities. Our suite of RL agents (StowAI, StackAI, JobAI) shows how closed-loop optimisation reduces rehandles, balances workloads, and shortens driving distances. As a result, terminal management shifts from firefighting to strategic control, leading to a measurable rise in container port throughput and improved container handling across the yard.

conclusions and future research directions for smart port and maritime terminal evolution

First, synthesise the quantified gains. Across automation, data science, stacking optimisation, and improved connectivity, terminals commonly achieve 10–20% productivity increases. For example, automation and big data have produced double-digit improvements in moves per hour and lower dwell times (industry overview). Also, simulation-driven stacking changes often yield a 10–12% uplift and fewer reshuffles.

Second, prioritise integration. Combine IoT sensors, real-time platforms, and a modern TOS so that the terminal operator sees a coherent state. Then, layer AI that can adapt to changes rather than imitate the past. In addition, ensure governance and explainability so teams can trust automated recommendations and maintain operational control.

Third, recommend technologies for future exploration. IoT, blockchain for secure interchange, and digital twins are essential for a smart port. Moreover, research should probe autonomous rail links, AI-driven multimodal optimisation, and predictive models that tie yard states to hinterland schedules. For practical AI approaches to complex planning tasks, see our work on reinforcement learning for port operations.

Fourth, invest in open simulation frameworks and field trials. Use sandboxes to validate AI policies and TOS integrations before live rollouts. Also, publish findings on how automation affects vessel turnaround, yard density, and operator workloads. That transparency helps the wider maritime and logistics community learn quickly.

Finally, focus on people, process, and technology together. Train operators to interpret AI recommendations. Next, keep continuous improvement loops active. As a result, terminals can transition from reactive firefighting to proactive optimisation. If your team wants to improve container terminal productivity, choose a staged path that measures gains, protects service, and scales proven practices. Consequently, ports and maritime terminals will adapt to rising global container demand, while preserving reliable service for shipping lines and hinterland partners.

FAQ

What are the key metrics to measure container terminal productivity?

Moves per hour, dwell time, and throughput are the core indicators that show how well a terminal performs. In addition, crane utilisation and truck turnaround time provide operational context and help identify where to focus improvement efforts.

How can terminals use simulation to test stacking strategies?

Terminals run discrete-event simulation models to test single-cycle, double-cycle, and proximity stacking under varied arrival patterns. Then, they compare reshuffle counts, travel distances, and crane conflicts to choose the best strategy for their layout.

What role does automation play in reducing dwell time?

Automation standardises move times and reduces variability in handling, which cuts dwell and increases steady moves per hour. Also, combining AGVs with real-time scheduling reduces manual handoffs and shortens truck queues.

How do appointment systems improve gate performance?

Appointment systems align truck arrivals with yard capacity so gates see fewer peaks and less queuing. As a result, gate throughput becomes predictable and the terminal can allocate equipment more effectively.

Can AI replace experienced planners at terminals?

No. AI complements experienced planners by proposing policies and handling routine allocation. Also, AI provides consistent suggestions so operator decisions become more stable across shifts and less reliant on individual tribal knowledge.

What infrastructure changes most reduce bottlenecks at a port?

Dedicated truck lanes, extended gate hours, and stronger rail connections reduce queuing and hinterland congestion. In addition, improved yards and separated flows for empty and full containers lower stacking conflicts.

How do I measure the ROI of automation projects?

Track changes in moves per hour, dwell time, and equipment utilisation before and after deployment. Also, calculate reduced fuel, labour hours, and fewer rehandles to capture full operational savings.

When should a terminal use reinforcement learning versus traditional simulation?

Use reinforcement learning when you need policies that adapt to changing mixes and constraints and when historical data is limited. Meanwhile, traditional simulation remains valuable for validation, scenario testing, and stakeholder sign-off.

What is the best way to reduce rehandles in the yard?

Optimise container stacking policies and use predictive placement rules to protect future moves; this reduces reshuffles. Also, coordinate quay stow planning with yard allocation to limit unnecessary shifters.

How do smart ports support the wider supply chain?

Smart ports improve predictability and throughput, which helps shipping lines, truckers, and rail operators plan better. Consequently, improved terminal performance reduces delays across the supply chain and lowers overall costs.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.