Category: Uncategorized

Integrated quay crane scheduling for container terminals

Overview of container terminals and quay crane operations Container terminals move boxes between ships and landside transport. They sit at the centre of maritime logistics, and they depend on reliable handling equipment. Quay cranes perform the primary task of ship-to-shore transfers. These cranes lift containers from container ships and place them onto trucks, agvs or […]

AI quay crane scheduling in container terminals

Artificial Intelligence (AI) and Port Operations at Tangier Med Container Terminal AI now drives large shifts in how a modern port runs. First, Tangier Med container terminal faces typical inefficiencies: manual gate checks, uncertain yard placements, and uneven crane allocation. Second, these issues slow vessel turnaround and increase operational costs. Third, terminal operators measure performance […]

Container terminal decision support systems explained

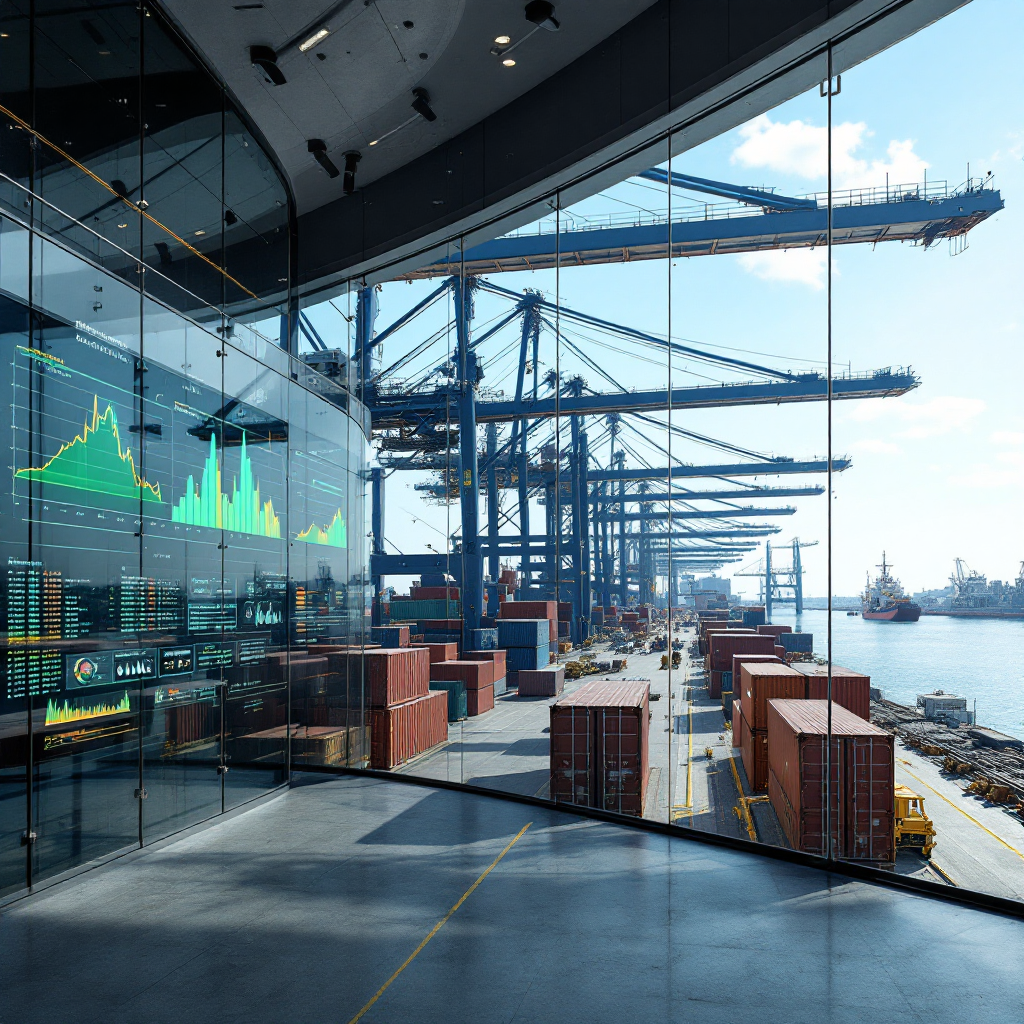

Understanding container terminal Decision Support Systems A Decision Support System in a container terminal helps people make better, faster choices. It pulls data from many sources. Then it runs scenarios, and it suggests actions. The platform supports scenario simulation, resource scheduling, and performance monitoring. For example, a well-designed decision support system can simulate peak windows […]

RTG job prioritization in high-density container terminals

container terminal layout and rubber tyred gantry fundamentals High-density container terminal layout begins with a clear yard grid and efficient lanes for trucks, and for RTG movement. In many terminals the yards sit parallel to the quay and they sit perpendicular to the quay in other designs, and each variation affects stacking capacity and throughput. […]

Predictive analytics for optimising port operations

predictive Planning in the maritime industry Predictive planning and reactive planning describe two very different approaches to how a port runs each day. Predictive planning uses forecasts, historical patterns and sensor feeds to anticipate vessel arrivals, cargo volumes and resource needs. By contrast, reactive planning waits for events and then responds. In a busy deepsea […]

Reducing carbon footprint in container ports

Understanding the Carbon Footprint of Port and Vessel Operations for Container Vessels Defining the CARBON FOOTPRINT of container vessels and a container port requires clarity. In this context, carbon footprint covers direct and indirect carbon dioxide and related greenhouse gas emissions from ship engines, cargo handling, on-site energy use, and land-side transport. Together, these activities […]

Container terminal vessel planning optimisation tools

Optimization in Container Terminal Workflow Optimization in a terminal context means matching resources to demand and doing so fast and accurately. It covers scheduling, allocation, tracking, and decision support. The aim is to reduce waits and to improve flow of goods and to lower costs. In practice, teams seek to maximize throughput and to minimize […]

Terminal simulation: digital replica of terminal operations

Terminal and Port Operations: Key Challenges and Context A terminal sits at the heart of global trade. It links ships, trucks, rail and warehouses, and it defines how goods flow through supply chains. For the modern terminal, speed and accuracy matter. For this reason, terminal management must handle high volumes, tight schedules and mixed cargo […]

Crane productivity optimisation in port operations

Crane Productivity in Container Terminals Crane productivity measures how fast a quay crew moves containers. In practice, teams report moves per hour (MPH) or gross moves per hour (GMPH) as the clear metric for operational performance. First, this metric links directly to berth utilization and vessel waiting times. Faster MPH shortens vessel time on berth […]

Container terminal stowage planning for stability and safety

container terminals: Role in maritime stowage planning Container terminals act as the key interface between shipping lines and port operators. They handle incoming and outgoing container flows, coordinate yard moves, and feed data to stowage planners. For operations teams, terminals supply container dimensions, weight classes, and the presence of special cargo such as dangerous cargo […]