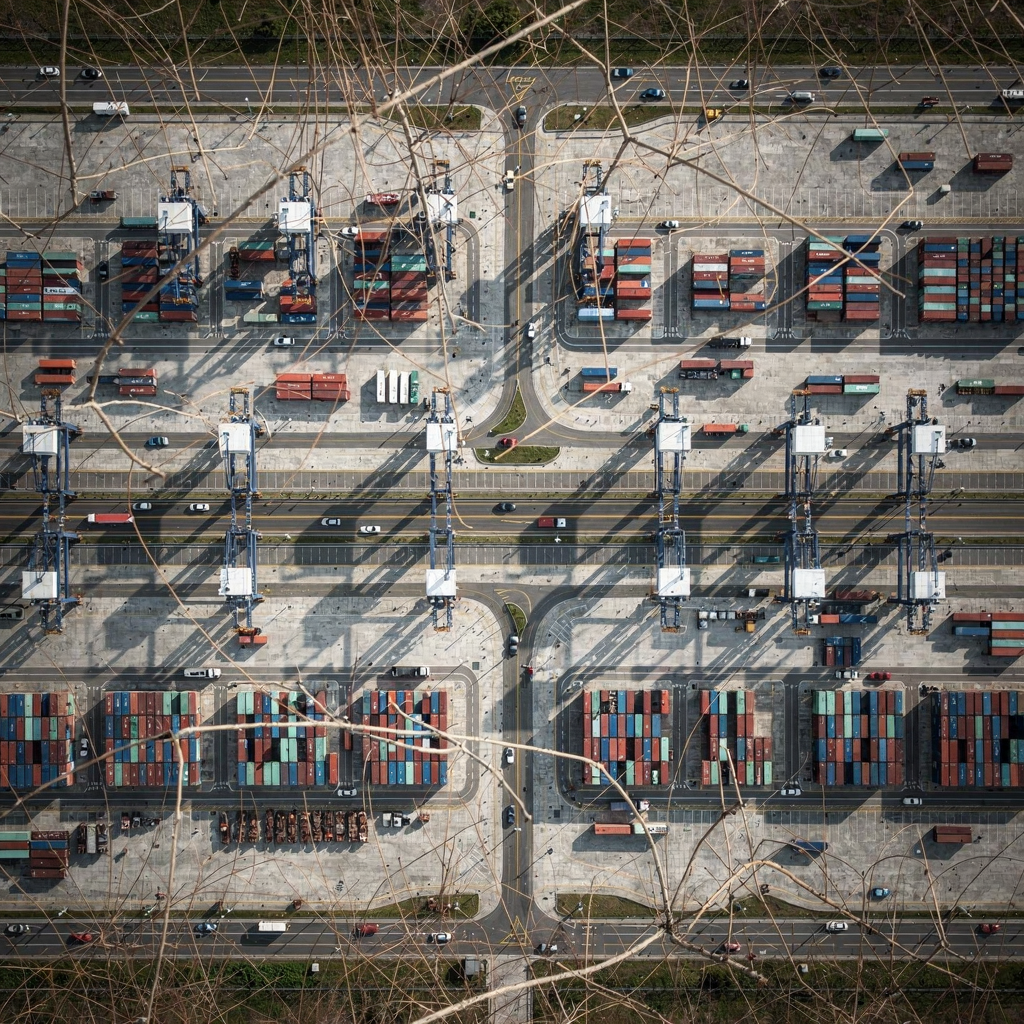

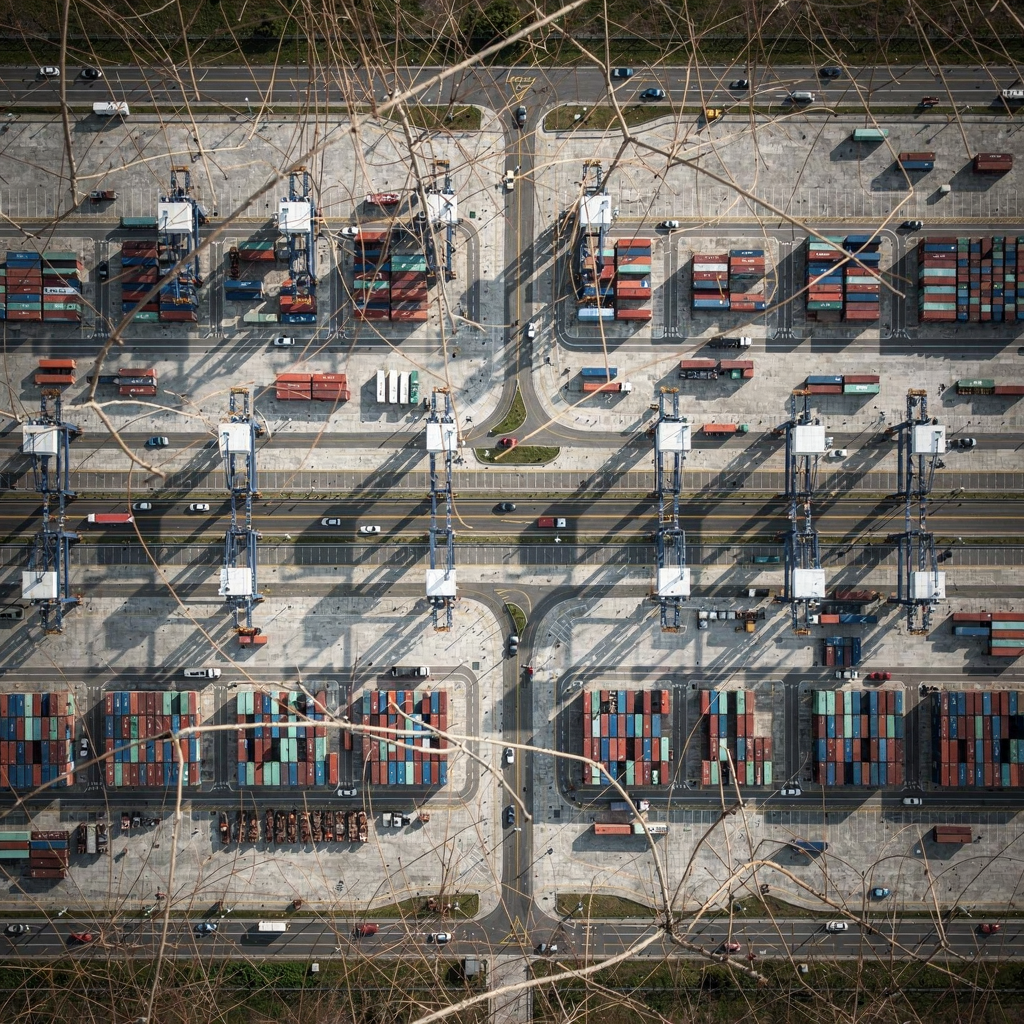

Introduction to AGV Operations in Container Terminals

Automated Guided Vehicles transform how terminals move containers. In ports, AGVs link quay cranes, yards and gates. They shuttle containers between quay crane work faces and storage blocks. Also, they reduce manual handling and speed up handoffs. For example, a quay crane delivers a box to an AGV. Then the AGV carries it to the assigned yard slot. Next, a yard vehicle or truck takes the container to the gate. The coordinated flow keeps cranes productive, and it lowers idle time.

Terminals operate under tight constraints. They must reduce travel time, avoid congestion and cut costs. Therefore, planners focus on throughput, energy use and waiting time. In addition, modern terminals face a dynamic and stochastic terminal environment. Ship arrival patterns change, crane productivity fluctuates, and gate peaks appear. As a result, static rules and simple heuristics often fail. For this reason Loadmaster.ai trains RL agents in a digital twin to plan and adapt. For instance, our JobAI coordinates moves across quay, yard, and gate to cut wait times and keep equipment busy. This approach reduces firefighting for planners, while also protecting crane productivity and yard balance.

Vehicles in automatic container terminal landscapes must handle uncertainty. Furthermore, planners handle thousands of constraints in real time. Also, storage layouts, weather, and vessel mixes change by the hour. Consequently, the planning system must be responsive and robust. Research on agv scheduling highlights that algorithms must balance multiple objectives under uncertainty. For concrete metrics, improvements in scheduling and execution have cut AGV waiting times by up to 30% in some studies, which boosts moves per hour and reduces energy use (UNSIGNED PROOF). In addition, digital twins and analytics can improve operational efficiency by more than 15% (digital twin study). Therefore, terminals that combine good dispatch logic with adaptive AI see steady gains. Finally, planning in automated container terminals requires integrated scheduling, tight telemetry, and clear KPIs. For more on job-level coordination and transport scheduling, see our discussion on internal terminal transport job scheduling internal terminal transport job scheduling.

routing Fundamentals: Dijkstra Path Planning and Obstacle Avoidance

Routing starts with shortest-path calculations. For that reason many systems use classical graph methods. In fact, dijkstra algorithm is used to compute the shortest path on a static map. Thus, planners map aisles, lanes and waypoints into nodes and edges. Then the algorithm returns the minimal travel cost path. Also, terminals layer speed limits and turn penalties into edge weights. As a result, computed paths match real travel times more closely.

However, container terminals are rarely static. Dynamic obstacles such as moving AGVs, trucks and temporary work zones appear. Therefore, the system must update maps in real time. In practice, path planning of automated guided setups includes both static graph search and dynamic re-planning. For example, a planned edge may become blocked if a crane enters an aisle. Then the AGV must follow a conflict-free path or wait safely. To avoid collisions, many sites add reservation tables or time-expanded graphs. These approaches reserve space-time slots for each guided vehicle. Consequently, systems can avoid deadlocks and reduce rehandles.

Integration with Geographic Information Systems helps. GIS provides coordinate accuracy and spatial queries. In addition, GIS layers enable planners to factor in yard elevation, slope, and lane widths. Moreover, when terminals deploy multiple lanes and parallel routes, planners can evaluate alternate corridors fast. For performance, mixed integer models sometimes sit behind higher-level dispatchers to validate schedules. Yet, for on-the-ground movement, a lightweight Dijkstra or A* search often handles immediate reroutes. Specifically, path planning in automated container environments benefits from hybrid methods that mix dijkstra-style graph search and local obstacle avoidance heuristics.

Finally, safety and operational constraints must be enforced. For instance, planners model minimum separation, speed profiles, and braking distances. Then the routing engine issues actionable control points to the automated guided vehicle system. In addition, planners audit reservations and conflicts so dispatchers can intervene when needed. This combined approach reduces delays, lowers the cost of AGV travel, and helps solve scheduling and path conflicts during peaks.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

scheduling and routing with Heuristic and Metaheuristic Algorithms

Heuristic and metaheuristic algorithms play a large role in container terminals. First, Genetic algorithm and Ant Colony Optimisation remain popular. In addition, Particle Swarm Optimisation and Tabu Search algorithm appear in research and pilots. These methods handle multi-objective trade-offs well. For example, they can optimize travel time, energy use and throughput simultaneously. Also, they often offer near-optimal solutions within practical compute times. As a result, terminals can run overnight or real-time batch optimizations without stalling operations.

Scheduling addresses both task allocation and sequence. Specifically, the agv scheduling problem couples assignment of tasks to vehicles and the order of execution. Therefore, planners often adopt a two-stage approach. First, a metaheuristic assigns tasks to AGVs and generates sequences. Then, a path planner refines trajectories and ensures conflict-free path execution. This integrated scheduling optimization reduces idle movement and unnecessary rehandles. In practice, a good scheduling model balances crane and yard workload and preserves executability under delay.

Also, research shows that heuristics scale well to yard sizes that classical MIP models find hard. For instance, genetic algorithm to solve large-scale assignment instances often outperforms exact solvers in runtime. Yet, mixed integer components still help validate constraints and set baselines. In addition, combined approaches such as hybrid GA with local search deliver improved solutions. For storage layout and vehicle allocation, planners use dual-cycle strategies and container storage and vehicle scheduling patterns to reduce reshuffles. For details on cost and equipment allocation, review techniques like dual cycling in terminal operations implementing dual cycling.

Furthermore, heuristics make it practical to include many real-world objectives. For example, a scheduling framework might weight drive time, quay idle time, and energy consumption. Then the optimizer searches policy space to meet those weights. Also, in brownfield projects where changes must fit legacy layouts, metaheuristics adapt without requiring full redesigns. For more on greenfield versus brownfield choices, see our comparative analysis brownfield vs greenfield port automation. Finally, heuristics allow planners to include operational rules, such as no-crossing lanes, preferred staging areas, and time windows for gate arrivals.

scheduling and routing using AI and Reinforcement Learning

Reinforcement Learning offers a fresh approach to adaptive scheduling and routing. First, RL models learn policies by interacting with a simulated terminal. Then they improve decision-making over many episodes. As a result, agents discover strategies that account for future consequences. For example, an RL-driven dispatcher may delay a move now to protect crane productivity later. Consequently, the terminal avoids reactive firefighting and reduces rehandles.

Research shows that reinforcement learning for logistics can handle dynamic rewards and stochastic events (RL for logistics). In practice, Loadmaster.ai uses a digital twin to train RL agents without depending on historical data. First, the simulator generates millions of scenarios. Next, the RL agents learn policies that respect guardrails and explainable KPIs. Then the trained agents deploy alongside a TOS. As a result, terminals gain resilience and balanced decisions across quay, yard, and gate. For details on simulation-first AI, see our article on simulation-driven terminal optimization simulation-first AI for inland terminals.

Reward design, environment interaction and policy training matter. Specifically, the reward must reflect mixed objectives such as throughput, energy and fairness. Also, constraints like collision avoidance and crane priorities act as hard guards. In tests, RL solutions adapt to sudden crane slowdowns and gate surges with minimal human input. For example, a production terminal achieved measurable throughput gains after deploying closed-loop RL agents, while also cutting driving distance and stabilizing shift-to-shift performance. Moreover, real-time retraining and online refinement let the agents accommodate new vessel mixes and yard layouts without full rework.

Finally, RL integrates with existing heuristics. For instance, an agent can propose sequences, while a classical path planner ensures conflict-free execution. Also, RL can manage dispatch at scale by issuing high-level policies and letting low-level controllers handle local collision avoidance. This hybrid approach combines the strengths of model-free learning with proven path planning methods. Thus, it offers practical deployment pathways for terminals seeking robust automation and continuous improvement.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Performance Metrics and Case Study Insights

Measuring AGV performance requires clear indicators. Key metrics include average waiting time, travel distance, and system throughput. Also, system utilization and crane productivity rank high. For example, a port study reported up to a 30% reduction in AGV waiting time after improved scheduling, which raised effective throughput (performance study). In addition, digital twins and analytics contributed to more than 15% efficiency gains in some terminals (digital twin research). Therefore, operators see both operational and environmental benefits.

Another practical issue is data handling. For AGV telemetry and command streams, network performance matters. For instance, upgrading industrial routers and switches can raise data throughput dramatically, which reduces packet loss and delays in command execution (router analysis). Consequently, terminal teams must treat OT networking as part of scheduling reliability. Also, capturing live telemetry enables continuous evaluation of the scheduling model and the scheduling optimization model that supports the AI.

Case examples underline the value of integrated tools. In trials, combining heuristic assignment with RL dispatch reduced unnecessary shifters and balanced RTG workloads. Also, when planners added a digital twin, they could test new crane and AGV assignments in simulation first. Furthermore, “Maritime ports are pivotal in global trade and economic prosperity, and the deployment of intelligent AGV systems is transforming terminal efficiency and sustainability” Dr. Notteboom. In operational rollouts, terminals focus on modular integration, low-latency processing, and human-in-the-loop exception handling. For practical implementation patterns, consult our work on interfaces for data exchange with terminal operating systems interfaces for data exchange with existing port operations TOS.

Lastly, quantitative targets help track progress. Operators measure reduction in travel distance and fuel use, crane idle reduction and consistency across shifts. Also, they compare metrics before and after deploying agents to prove value. In many cases, balancing KPIs reduces overall cost of AGV operations and helps meet sustainability targets, including lower emissions from shorter routing and fewer empty moves.

Challenges and Future Directions in AGV Scheduling and Routing

Challenges remain in real-time responsiveness and data integration. First, systems must process telemetry, schedules and events at low latency. Also, they need robust fallbacks when sensors fail. For example, planners must handle packet loss and intermittent network issues without halting operations (industrial router case). Therefore, architecture matters. Designers favor cloud-native software with local edge processing to guarantee responsiveness. In addition, terminals often require TOS-agnostic integration so new modules plug in without replacing core systems.

Advances in autonomous vehicle technologies and AI adaptability will shape the next wave. For instance, enhanced perception and local obstacle avoidance reduce dependence on global reservations. Also, integrating spatial data and GIS improves route feasibility and safety. Moreover, research on planning for multiple autonomous guided vehicles highlights the need for coordinated multi-agent path planners. Similarly, conflict-free path planning in automated yard operations reduces deadlocks and bottlenecks. At the same time, validation methods like mixed integer proofs still help certify feasibility.

Looking ahead, a fully automated, self-optimising terminal ecosystem seems feasible. However, that vision demands robust scheduling frameworks, validated safety layers, and clear governance. For example, operators need explainable policies and audit trails to meet regulatory standards. In addition, terminals must manage KPI trade-offs such as quay crane throughput versus yard congestion. Loadmaster.ai addresses this need by training adaptive agents that weigh those trade-offs dynamically. Also, our cold-start ready RL agents require no historical data; instead they learn in simulation and then refine online, which reduces deployment risk.

Finally, practical methods matter. Short-term steps include improving integration, deploying digital twins for scenario testing, and adopting hybrid optimization models that mix heuristics and learning. For deeper implementation guidance, see our digitalisation roadmap and work on low-latency processing for terminal AI terminal operations digitalization roadmap, low-latency data processing. Ultimately, terminals that combine robust scheduling, effective routing, and adaptive AI will cut costs, reduce emissions, and deliver more stable throughput. Moreover, they will operate with predictable, repeatable performance rather than ad-hoc human-dependent decisions.

FAQ

What is agv scheduling and routing?

AGV scheduling and routing refers to assigning tasks to AGVs and planning their paths. It ensures that vehicles move containers between quay, yard, and gate efficiently and safely.

How does Dijkstra relate to AGV path planning?

Dijkstra’s algorithm computes shortest-path solutions on a graph model of the yard. It provides a reliable baseline for path planning, especially for static maps and initial route proposals.

Can reinforcement learning improve AGV dispatch?

Yes. Reinforcement Learning trains agents to balance competing KPIs and adapt to changing conditions. In practice, RL agents can reduce waiting time and rebalance yard workloads through policy learning.

What metrics should terminals track for AGV performance?

Terminals track average waiting time, travel distance, throughput, and crane utilisation. These indicators help quantify gains from scheduling optimization and routing improvements.

Do heuristics still matter for scheduling?

Absolutely. Heuristics and metaheuristics scale to large problem sizes and provide near-optimal solutions quickly. They complement exact models and learning-based methods in hybrid systems.

How important is data infrastructure for AGV systems?

Data infrastructure is critical for reliable AGV operations. Low-latency telemetry and robust networking reduce command delays and help maintain safe, conflict-free paths.

What role do digital twins play in implementation?

Digital twins let teams simulate millions of scenarios without risking live operations. They enable cold-start training for RL agents and validate scheduling models before deployment.

How do terminals avoid collisions between AGVs?

Terminals use reservation systems, time-expanded graphs, and local obstacle avoidance to enforce separation. These methods create conflict-free path plans and reduce deadlocks.

Is it possible to start without historical data?

Yes. Simulation-trained RL agents can learn effective policies without historical logs. Loadmaster.ai uses this approach to avoid inheriting past inefficiencies.

What is the future of AGV scheduling in terminals?

The future emphasizes adaptive AI, integrated scheduling frameworks, and self-optimising ecosystems. Terminals that adopt these approaches can improve efficiency and resilience while lowering costs.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.