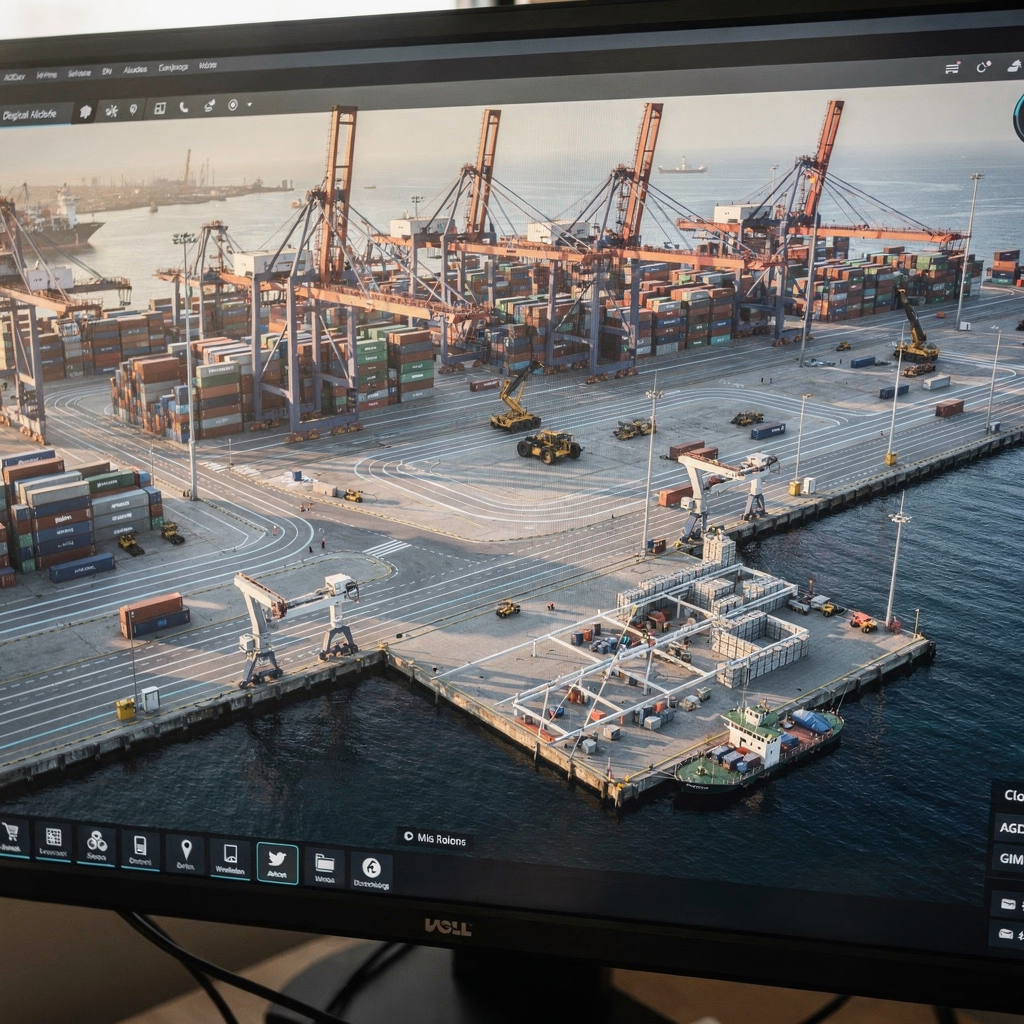

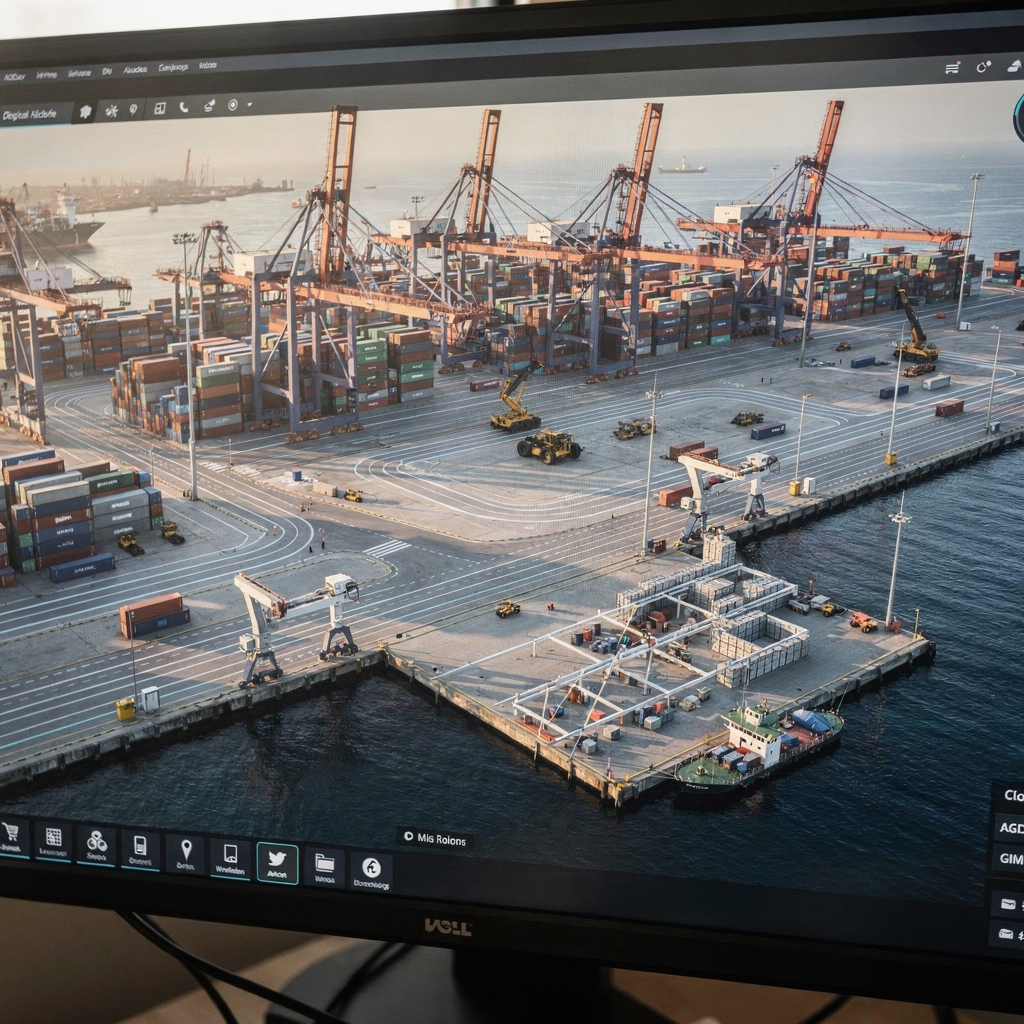

DISCRETE EVENT SIMULATION MODEL for Automated Container Terminal Operations

Discrete event methods have long been a standard for modeling flows in complex logistics. A discrete event approach maps key occurrences—arrivals, allocations, and completions—onto a timeline so planners see cause and effect. For an automated container terminal the fit is natural because the system advances in countable moves and decision points. For example, a ship call generates container arrivals, cranes swing, and then automated guided vehicles arrive to collect loads. This description helps a reader understand how a terminal operation is expressed as a set of events.

In a practical model, container arrivals become arrival events, quay crane picks become service events, and yard placements become storage events. The discrete event simulation model captures stochasticity, queueing, and resource contention, and it supports experimentation with rule changes and resource levels. A fully instrumented model can also incorporate agent-based simulation to represent decision-makers and automated agents, and then compare results. The simulation represents handling operations at fine granularity, and it supports what-if planning when berth schedules slip or when gantry crane availability changes.

Key outcomes include metrics such as moves per hour at the quay, truck waiting time at the gate, and container storage patterns in the container yard. Using discrete event logic, a model can analyze how a change in crane cycles cascades into yard congestion so staff and systems respond faster. For planners and terminal operators there is clear value: it allows prediction of vessel delays and of peak queueing, and it supports policies that reduce rehandles. For example, a published digital twin approach embeds discrete event logic to assess resilience and sustainability, offering “unprecedented insight into terminal operations” when combined with live data [UNPROTOF Container terminal digital twin modeling]. Loadmaster.ai uses this same event-driven framing when we train RL agents inside a virtual environment that mirrors real layout and rules.

Simulation Model Development in AnyLogic for Automated Container Terminal

AnyLogic is a flexible software tool that blends discrete event, agent-based, and system dynamics paradigms. In practice, modelers define quay cranes, AGV flows, yard blocks, and truck interfaces as components. AnyLogic support makes it simple to link a visual layout to resource pools, route networks, and decision logic. The core elements in a typical terminal simulation include quay cranes, automated guided vehicles, container yard stacks, the gate, and a berth scheduling module. In the model, quay crane cycles are parameterized, AGV travel times are modeled with variability, and yard operations follow stacking rules.

Data requirements are substantial. You need arrival patterns, handling times, equipment parameters, container storage policies, and service level targets. Calibration is done by tuning distributions and matching historical KPIs such as moves per hour and average truck waiting time. When a simulation model is developed we validate it against observed terminal throughput and berth occupancy. For short-term forecasting, studies show predictive accuracy for robotized terminals up to eight hours ahead when models are well-calibrated [robotized maritime container terminals]. That window supports real-time dispatch decisions and schedule smoothing.

Modelers run simulation experiments to test layout and operations choices, to evaluate equipment counts, and to trial alternative yard strategies. The simulation tools in AnyLogic allow integration with live feeds so a digital twin can replay telemetry and update state. In an AnyLogic model the AGV routing logic, the crane sequencing, and the gate service are all modular. This modularity enables integrated simulation of landside, quay, and yard interactions and supports port authorities in planning construction of new blocks or changes to length and width of berths. For more on interfacing models with operational systems see our guide to interfaces for data exchange with existing TOS.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Performance Metrics in Container Terminal Operations and Port Supply Chain

Choosing the right metrics guides decisions and clarifies trade-offs. Key indicators include terminal throughput, crane productivity, AGV utilization, queue lengths, and service level at the gate. Throughput measures moves per hour realized across quay and yard and it connects directly to ship schedules and to port throughput targets. Crane productivity captures effective crane work time verses idle time, and utilization shows how intensively equipment is used. These metrics make it possible to compare scenarios objectively, and they are central when performing terminal performance and cost trade-offs.

Simulation outputs are used to feed higher-level supply chain models. For instance, predicted vessel delays and truck waiting time feed inland terminal and hinterland schedules, and they inform intermodal carriers about expected arrival patterns. An integrated simulation that links quay, yard, and landside allows planners to assess container flows for inbound and outbound moves and to model transshipment throughput under peak conditions. For port management this is critical because a small change at the quay often amplifies across rail and road links.

Quantitative studies show that changes in the number of cranes and their kinematic parameters alter throughput nonlinearly; adding a crane improves productivity until yard congestion reduces marginal gains [modelling and simulation of ship-to-shore]. That result illustrates the need for combined metrics: high crane moves/hour paired with rising queue lengths is not acceptable. Simulation provides a controlled way to measure service level under different resource mixes, and it supports optimization of equipment counts and positions. For readers who want practical methods, our work on equipment allocation and dual-cycling explains trade-offs between quay productivity and yard quality.

Case Study: Maritime Container Terminal Operations at a Container Port

This case study models a mid-size container port with two berths, three quay cranes, and a yard of mixed block and high-rise automated stacks. The scenario design included a baseline schedule and a disruption scenario where one berth loses a crane for two hours. The simulation model developed for this site included arrival schedules, gantry crane cycle distributions, AGV routing rules, and container storage policies. The model was built to analyze ship loading and unloading rates, truck turnaround, and overall port system resilience.

The baseline scenario showed steady throughput and acceptable truck waiting time. The disruption scenario demonstrated how crane downtime causes immediate increases in berth occupancy and vehicle queues. The simulation-based results matched observations within an eight-hour predictive horizon, which aligns with published findings for robotized maritime terminals that report accurate short-term forecasts [robotized maritime container terminals]. The case study shows how simulation can identify which yard blocks will hit capacity, which stacks need reshuffling, and which truck lanes will exceed acceptable waiting times.

We also compared alternatives: adding one gantry crane at the second berth, reallocating AGV cycles, and applying rearrangement policies in the container yard. The optimized plan reduced rehandles and maintained moves/hour while lowering truck waiting time. The case study shows how simulation experiments inform practical decisions and how a digital twin ties the model to live data to allow continuous refinement. For readers interested in how to go from rules to AI, see our post on from rule-based planning to AI optimization. The result supports claims that simulation provides planners with a safe sandbox to test resilience strategies and to measure performance under stress.

Drowning in a full terminal with replans, exceptions and last-minute changes?

Discover what AI-driven planning can do for your terminal

Simulation and Optimization of Automated Container and AGV Systems

Optimization routines are layered atop simulation to find control policies that meet multiple KPIs. Simulation-based optimization runs many scenarios, evaluates outcomes, and uses algorithms such as heuristic search, genetic algorithms, or reinforcement learning to improve decisions. For AGV routing and crane allocation, heuristics can perform well in routine traffic, and RL agents can discover non-intuitive policies when traffic patterns vary. Loadmaster.ai uses reinforcement learning agents to search policy space and to balance quay productivity versus yard congestion and driving distance.

Trade-offs are central. Increasing AGV counts reduces waiting at the quay but raises utilization and cost, and adding cranes can increase throughput but may create yard bottlenecks. Optimization helps quantify these trade-offs by running simulation experiments under varying demand. A common approach is to embed an optimization layer that proposes resource allocations, runs a fast simulation, and then refines the allocation. This simulation approach supports decisions such as whether to prioritize ship loading and unloading or to protect yard flow when landside demand spikes.

Practical algorithms often mix rule-based controls with learned policies so safety constraints and operational guardrails remain enforced. That hybrid path reduces the need for long historical datasets and supports cold-start deployments, since agents can be trained inside a digital twin without real operations data. When applied to automated equipment, the combined simulation and optimization process produces measurable improvements in moves/hour, lower rehandles, and higher equipment utilization. For more on AGV logic and scheduling see our technical note on AGV routing and scheduling algorithms.

Future Trends in Terminal Operation with Digital Twin Integration

Digital twin frameworks are shifting terminal analytics from static models to live, adaptive systems. A digital twin embeds streaming telemetry into a simulation so the model mirrors the physical state and then projects outcomes under candidate actions. This integrated simulation capability supports AI-driven control, synchro-modal planning across rail and road, and sustainability assessments such as energy use and emission reduction. For instance, a digital twin can compare the environmental impact of different yard strategies and support emission-reduction targets.

Emerging areas include tighter links between port systems and inland terminals, inclusion of automated rail, and the growth of high-rise automated stacking that changes container storage patterns. Future research will extend models to capture synchro-modal choices and to tie port throughput to hinterland capacity. Researchers note that credibility hinges on good input data and validation, and that better models enable better resilience planning [Simulation Credibility – NASA]. Digital twins that incorporate agent-based modules can also test human-in-the-loop workflows for exception handling, which helps port authorities and terminal operators manage disruptions.

Finally, practical deployments will emphasize integration with existing Terminal Operating Systems and low-latency data pipelines so AI can operate with governance and safety. Loadmaster.ai’s approach uses a sandboxed digital twin to train RL agents against operational KPIs, and then deploys policies with guardrails to live operations. This path reduces reliance on historical data and produces stable, repeatable gains in efficient operations and in consistent service levels. For those planning pilots, resources exist on implementing digitalization roadmaps and on the ROI of automation projects terminal operations digitalization roadmap.

FAQ

What is a discrete event simulation model and why use it for container terminals?

A discrete event simulation model represents the system as a sequence of events that change state at specific times. It is well suited to container terminal operations because moves, crane cycles, and vehicle arrivals are naturally event-driven, and the model captures queueing, contention, and variability.

Can AnyLogic support combined discrete event and agent-based models?

Yes, AnyLogic permits hybrid modeling that integrates discrete event, agent-based, and system dynamics elements. That flexibility helps modelers represent both physical resources and decision agents within a single environment.

How do you validate a terminal simulation against real operations?

Validation uses historical KPI matching and scenario checks such as comparing predicted berth occupancy or moves/hour to observed values. Calibration adjusts distributions and parameters until the model reproduces key metrics and known bottlenecks.

What performance metrics matter most for terminals?

Moves per hour, crane productivity, AGV utilization, truck waiting time, and yard queue lengths are primary KPIs. Combined metrics help reveal trade-offs, for example between quay productivity and yard congestion.

How can simulation help with disruption planning?

Simulation experiments allow planners to run disruption scenarios, measure impacts on berth schedules and truck queues, and trial mitigation strategies without affecting live operations. This reduces risk and improves response plans.

Do reinforcement learning methods need historical data to work?

Not necessarily; RL agents can be trained inside a digital twin so they learn from simulated experience rather than from past records. This cold-start capability is useful where historical data are scarce or biased.

What is the role of digital twins in terminal management?

Digital twins connect simulation models to live telemetry, enabling real-time monitoring and predictive analytics. They support continuous optimization and quicker responses to changing conditions.

Are there standard tools for AGV routing and scheduling?

Several approaches exist, from heuristics to optimization and RL-based methods. Choice depends on scale, required responsiveness, and integration with control systems; hybrid designs often work best.

How do simulation and optimization handle multiple objectives?

Multi-objective optimization evaluates trade-offs between metrics such as throughput, utilization, and cost. Simulation provides the performance surface for algorithms to search and to identify balanced policies.

Where should terminals start when adopting model-driven planning?

Begin with a focused pilot: build a modest digital twin for a single berth or yard block, run scenarios, and validate results. Then scale the model and integrate with operational systems while keeping governance and safety controls in place.

our products

stowAI

stowAI

stackAI

stackAI

jobAI

jobAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.

stowAI

stowAI

Innovates vessel planning. Faster rotation time of ships, increased flexibility towards shipping lines and customers.

stackAI

stackAI

Build the stack in the most efficient way. Increase moves per hour by reducing shifters and increase crane efficiency.

jobAI

jobAI

Get the most out of your equipment. Increase moves per hour by minimising waste and delays.